Case study – Emulsification process optimization with instrumented micro-pilot approach

Industry : Ingredients

Type: Group

Department : R&D

The Client wishes to resolve issues appeared during the industrialisation of an emulsification process of high-viscosity product and asks Rheonis for operational recommandations

Optimising product/process thanks to instrumented micro-pilot approach

In this context, we provided this study with our know-how of product/process couplings and our unique approach of instrumented micro-pilot for complex products.

In this two phases study, we performed the following tasks :

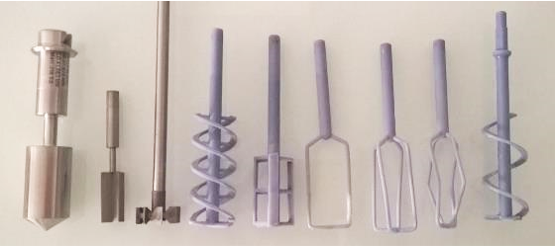

- Preliminary phase : Development of an instrumented mixing/agitation micro-pilot adapted for rheometry, Design of mixing geometries with 3D printing, Adaptation, validation and calibration on rheometer

- R&D Study of the processing-induced variabilities (on Client initial formula) and determination of optimised conditions

- R&D Study of formulation influencing factors on final product properties

- Conclusions on optimised product/process conditions and recommandations

Systemic action gauge

[PROGRESSBAR_WP id=6446]

Bridge the gap between R&D and scale-up

Our instrumented micro-pilot approach allows to study, in laboratory controlled conditions and with small amount of matter, the coupling effects between product and process and then define optimized conditions for reaching given final properties. Scale-up step is tremendously eased by such an approach avoiding usual trial-and-fail practices.

Mixing micro-pilot on rheometer allows to take advantage of the rheometer sensors and experimental environment. Preparation conditions , mixing conditions and ingredients introduction kinetics can be finely determined in order to achieve an emulsion with appropriate final properties under optimised product/process conditions.

Strengths of instrumented mixing micro-pilot

Study of both product and process influencing factors and identification of critical conditions

Experimental determination of optimised mixing geometries

Low consumption of matter and no use of industrial facilities (except for validation)

Quantified data and controlled conditions

Operational recommandations

You face any issue with industrial mixing of complex products ? Please feel free to contact us, we will be glad to discuss your subject.

Last Updated on 11 octobre 2021 by Vincent Billot